Project Description

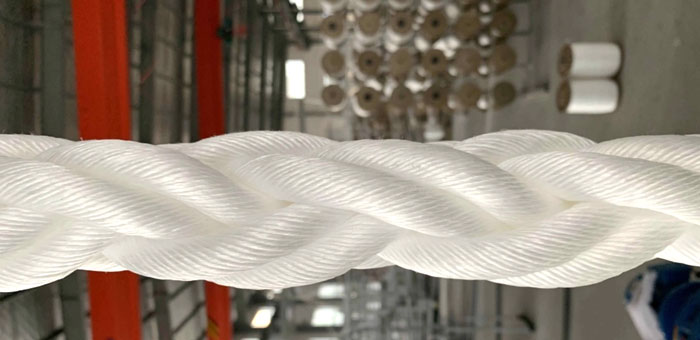

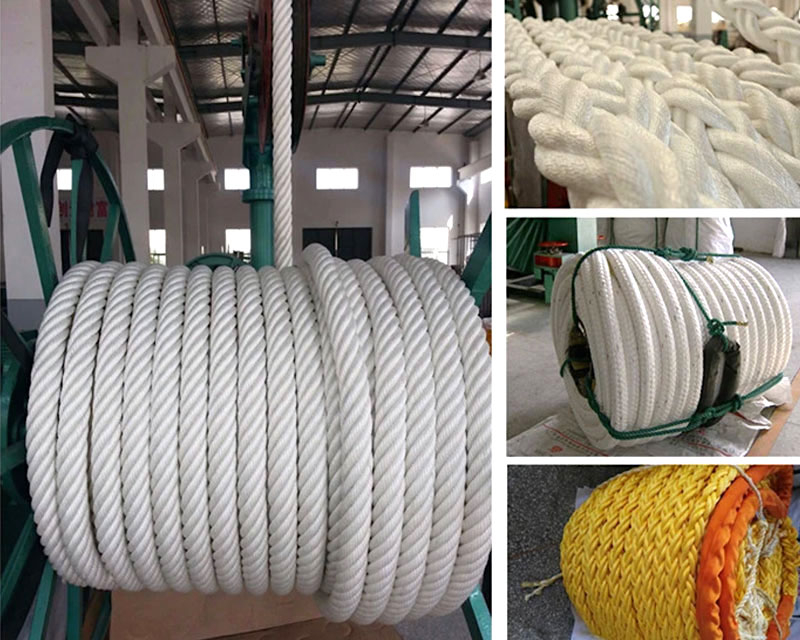

Polypropylene Rope

Polypropylene Rope, also know as PP Rope, is easy to handle, and it feels soft and smooth, and absorbs water, known as “floating nylon”. It widely used as mooring line, it has same strength either under wet condition or normal condition. It is easy operation, chemical corrosion resistance, drain well, keep in dark and dry place.

Product Features and Applications:

- Standards: ISO2307

- 8-strand, 12-strand

- Type: Monofilament & Multifilament

- Specific Gravity:0.91g/cm³, floating on the water

- Melting Point: 165℃

- Elongation: 12%

- Abrasion Resistance: normal

- UV Resistance: good

- Chemical Resistance: good

- Applications: widely used in marine mooring, sea farming, transportation, oil fields

- Packing: by reel, roll, bag

For more information and ex-stock availability, contact one of our sales engineer to help you choose the fittings suitable for your vessel. Please check our website for other chocks, mooring items, deck machinery, chains, anchors, etc.

| Size | Weight | Min. Breaking Force | Breaking Strength *MEG4 LDBF | ||||

|---|---|---|---|---|---|---|---|

| mm Dia. | Inch Cir. | g/m | kg/220m | KN | Ton | KN | Ton |

| 24 | 3 | 260 | 57.2 | 93 | 9.5 | 84 | 8.6 |

| 28 | 3-1/2 | 355 | 78.1 | 124 | 12.6 | 111 | 11.4 |

| 32 | 4 | 460 | 101.2 | 163 | 16.7 | 147 | 15 |

| 36 | 4-1/2 | 586 | 128.9 | 198 | 20.2 | 179 | 18.2 |

| 40 | 5 | 718 | 158.0 | 245 | 25.0 | 221 | 22.5 |

| 44 | 5-1/2 | 881 | 193.8 | 292 | 29.8 | 263 | 26.8 |

| 45 | 5-5/8 | 924 | 20. | 307 | 31.3 | 276 | 28.2 |

| 48 | 6 | 1040 | 228.8 | 350 | 35.7 | 315 | 32.1 |

| 50 | 6-1/4 | 1130 | 248.6 | 371 | 42.3 | 334 | 34.1 |

| 52 | 6-1/2 | 1220 | 268.4 | 414 | 45.5 | 373 | 38.0 |

| 55 | 6-7/8 | 1380 | 303.6 | 446 | 47.6 | 401 | 40.9 |

| 56 | 7 | 1420 | 312.4 | 467 | 53.6 | 420 | 42.9 |

| 60 | 7-1/2 | 1630 | 358.6 | 525 | 59.5 | 473 | 48.2 |

| 64 | 8 | 1850 | 407.0 | 583 | 61.4 | 525 | 53.6 |

| 65 | 8-1/8 | 1924 | 423.3 | 602 | 67.3 | 542 | 55.3 |

| 68 | 8-1/2 | 2095 | 460.9 | 659 | 71.2 | 593 | 60.5 |

| 70 | 8-3/4 | 2260 | 497.2 | 698 | 75.0 | 628 | 64.1 |

| 72 | 9 | 2340 | 514.8 | 735 | 83.2 | 662 | 67.5 |

| 75 | 9-3/8 | 2585 | 568.7 | 816 | 95.2 | 734 | 74.9 |

| 80 | 10 | 2910 | 640.2 | 933 | 106.4 | 840 | 85.7 |

| 85 | 10-5/8 | 3285 | 722.7 | 1043 | 113.1 | 939 | 95.8 |

| 88 | 11 | 3510 | 772.2 | 1108 | 120.6 | 998 | 101.8 |

| 90 | 11-1/4 | 3668 | 807.0 | 1182 | 133.2 | 1064 | 108.5 |

| 95 | 11-3/4 | 4099 | 901.8 | 1306 | 133.3 | 1175 | 119.9 |

| 96 | 12 | 4160 | 915.2 | 1307 | 145.8 | 1176 | 120.0 |

| 100 | 12-1/2 | 4530 | 996.6 | 1429 | 157.1 | 1286 | 131.3 |

| 104 | 13 | 4860 | 1069.2 | 1540 | 178.6 | 1386 | 141.4 |

| 112 | 14 | 5680 | 1249.6 | 1750 | 202.4 | 1575 | 160.7 |

| 120 | 15 | 6510 | 1432.2 | 1983 | 202.4 | 1785 | 182.1 |

| *LDBF: Line Design Break Force according to OCIMF MEG4 appedix B | |||||||

| **Other sizes are also available upon request | |||||||

- DOWNLOAD PDF

- Contact Us for Details !