Project Description

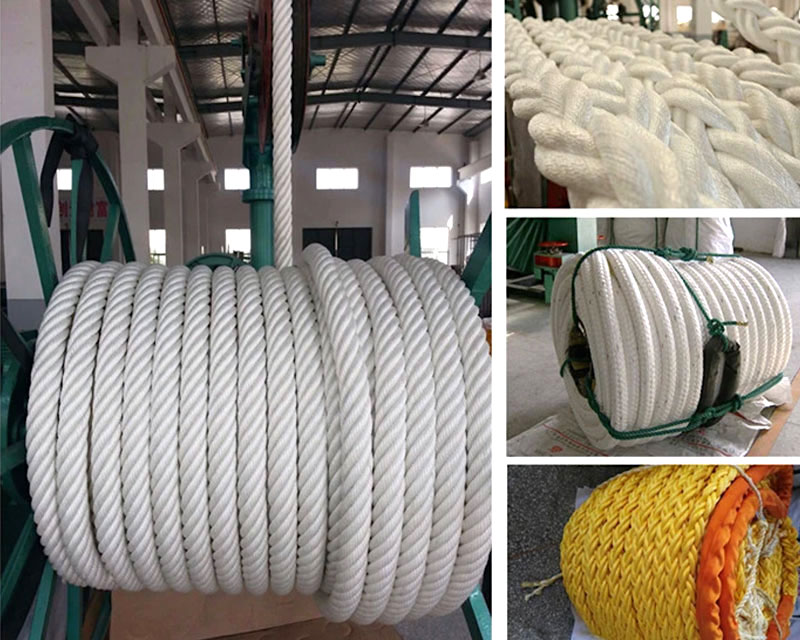

UHMWPE Rope

Product Features & Applications:

UHMWPE/HMWPE is a dyneema equivalent, with ultra high molecular weight polyethylene fiber and high technology. it’s high strength, light weight, low elongation.

- Stronger: for the same dia., the strength is the same as the wire rope

- Lower Elongation: the breaking elongation is close to the wire rope

- Lighter: in the same strength, the weight is only 1/8 of the wire rope, 1/4-1/5 of the nylon rope or polyester rope, 18%-20% of the polypropylene rope

- Smaller: in the same strength,the dia. of the UHMW PE rope is 55%-60% of the nylon rope or polyester rope,45% of the polypropylene rope

- Applications: winch rope, towing, mooring system for ultra large container ships, army and navy equipment, offshore, sports equipment, electrical communications, large precision object sling, etc.

For more information and ex-stock availability, contact one of our sales engineer to help you choose the fittings suitable for your vessel. Please check our website for other ropes, mooring items, deck machinery, chains, anchors, etc.

| Size | Weight | Type I | Type I | Type II &III | Type II &III | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Breaking Strength ISO MBF | Breaking Strength MEG4 LDBF | Breaking Strength ISO MBF | Breaking Strength MEG4 LDBF | ||||||||

| mm Dia. | Inch Cir. | g/m | kg/220m | KN | Ton | KN | Ton | KN | Ton | KN | Ton |

| 6 | 3/4 | 21 | 4.6 | 39 | 4.0 | 35 | 3.6 | ||||

| 8 | 1 | 40 | 8.8 | 71 | 7.3 | 64 | 6.5 | ||||

| 10 | 1-1/4 | 61 | 13.4 | 106 | 10.8 | 95 | 9.7 | ||||

| 12 | 1-1/2 | 83 | 8.3 | 150 | 5.3 | 135 | 13.8 | ||||

| 14 | 1-3/4 | 117 | 25.7 | 211 | 21.5 | 190 | 19.4 | ||||

| 16 | 2 | 151 | 33.2 | 267 | 27.2 | 240 | 24.5 | ||||

| 18 | 2-1/4 | 184 | 40.5 | 322 | 32.9 | 290 | 29.6 | ||||

| 20 | 2-1/2 | 227 | 49.9 | 384 | 39.2 | 346 | 35.3 | ||||

| 24 | 3 | 324 | 71.3 | 533 | 54.4 | 480 | 49.0 | ||||

| 28 | 3-1/2 | 444 | 97.7 | 704 | 1.9 | 634 | 64.7 | ||||

| 32 | 4 | 589 | 129.6 | 918 | 93.7 | 826 | 84.3 | ||||

| 36 | 4-1/2 | 720 | 158.4 | 1104 | 112.7 | 994 | 101.4 | 840 | 85.7 | 756 | 77.1 |

| 40 | 5 | 880 | 193.6 | 1329 | 135.6 | 1196 | 122.0 | 1027 | 104.8 | 924 | 94.3 |

| 42 | 5-1/4 | 979 | 215.4 | 1459 | 148.9 | 1313 | 134.0 | 1142 | 116.5 | 1028 | 104.9 |

| 44 | 5-1/2 | 1078 | 237.2 | 1589 | 162.1 | 1430 | 145.9 | 1258 | 128.3 | 1132 | 115.5 |

| 46 | 5-3/4 | 1171 | 257.6 | 1698 | 173.2 | 1528 | 155.9 | 1366 | 139.4 | 1230 | 125.5 |

| 48 | 6 | 1264 | 278.1 | 1807 | 184.4 | 1626 | 181.0 | 1475 | 150.5 | 1327 | 135.4 |

| 50 | 6-1/4 | 1388 | 305.4 | 1971 | 201.1 | 1774 | 196.1 | 1619 | 165.2 | 1457 | 148.7 |

| 52 | 6-1/2 | 1512 | 332.6 | 2136 | 217.9 | 1922 | 211.2 | 1764 | 180.0 | 1588 | 162.0 |

| 54 | 6-3/4 | 1636 | 359.9 | 2300 | 234.7 | 2070 | 226.3 | 1909 | 194.8 | 1718 | 175.3 |

| 56 | 7 | 1760 | 387.2 | 2464 | 251.5 | 2218 | 240.8 | 2053 | 209.5 | 1848 | 188.6 |

| 58 | 7-1/4 | 1885 | 414.7 | 2622 | 267.6 | 2360 | 255.1 | 2199 | 224.4 | 1979 | 202.0 |

| 60 | 7-1/2 | 2010 | 442.2 | 2778 | 283.4 | 2500 | 269.6 | 2345 | 239.3 | 2111 | 215.4 |

| 62 | 7-3/4 | 2135 | 469.7 | 2936 | 299.5 | 2642 | 284.0 | 2491 | 254.2 | 2242 | 228.8 |

| 64 | 8 | 2260 | 497.2 | 3092 | 315.5 | 2783 | 302.4 | 2637 | 269.0 | 2373 | 242.1 |

| 66 | 8-1/4 | 2423 | 533.1 | 3293 | 336.1 | 2964 | 321.0 | 3016 | 288.5 | 2544 | 259.6 |

| 68 | 8-1/2 | 2585 | 567.7 | 3496 | 356.7 | 3146 | 339.5 | 3206 | 307.7 | 2714 | 277.0 |

| 70 | 8-3/4 | 2748 | 604.6 | 3697 | 377.2 | 3327 | 358.0 | 3395 | 327.1 | 2885 | 294.4 |

| *MBF: Minimum Breaking Force according to ISO2307. **LDBF: Line Design Break Force according to OCIMF MEG4-Appendix B ***Other sizes are available upon request | |||||||||||

- DOWNLOAD PDF

- Contact Us for Details !