Project Description

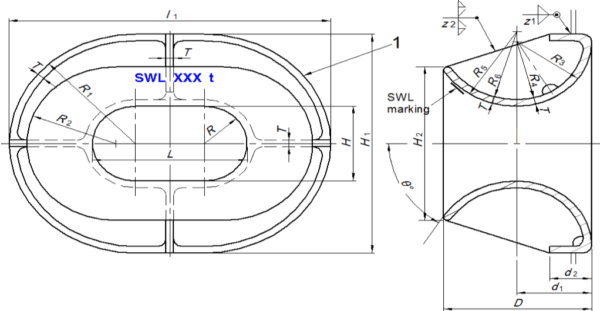

CHOCK – ISO13729 CLOSED MOORING CHOCK -TYPE B

Product Details:

- Bulwark Mounted Closed Type

- Size: 250×200/300×250/350×250/400×250/450×250/500x250A

- Capacity: SWL22ton to SWL140ton

- Finishing: 2-layer of shop primer after sand blasting 2.5

- Certificate: DNV-GL, BV, LRS, ABS, RINA, IRS, RS, CCS, KR, NK

Features & Inspection:

- The foundation of the closed chocks is to be determined in consideration of actual load direction. The foundation and welding connections to the hull are to be guaranteed reliable transmission of the maximum loading of the closed chocks to hull construction without any plastic deformation or cracks.

- The closed chocks are to be coated externally with an anti-corrosion protective finish.

- The closed chocks are to be clearly marked by weld bead or equivalent with its SWL. The SWL shall be expressed in tonnes (letter ‘t’) and be located so that it is not obscured during operation of the fitting.

For more information and ex-stock availability, contact one of our sales engineer to help you choose the fittings suitable for your vessel. Please check our website for deck machinery, chains, anchors, etc.

| Nominal size L x H x D | l1 | l2 | H1 | H2 | R | R1 | R2 | R3 | R4 | R5 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 250x200x214 | 516 | 441 | 466 | 306 | 100 | 233 | 153 | 108 | 96 | 150 | ||

| 300x250x286 | 638 | 554 | 588 | 410 | 125 | 294 | 205 | 144 | 128 | 180 | ||

| 350x250x333 | 736 | 646 | 636 | 449 | 125 | 318 | 224.5 | 168 | 150 | 200 | ||

| 400x250x381 | 834 | 736 | 684 | 450 | 125 | 342 | 225 | 192 | 172 | 250 | ||

| 450x250x381 | 884 | 786 | 684 | 450 | 125 | 342 | 225 | 192 | 172 | 250 | ||

| 500x250x381 | 934 | 836 | 684 | 450 | 125 | 342 | 225 | 192 | 172 | 250 | ||

| 400x250x428 | 882 | 778 | 732 | 515 | 125 | 366 | 257.5 | 216 | 194 | 250 | ||

| 450x250x428 | 932 | 828 | 732 | 515 | 125 | 366 | 257.5 | 216 | 194 | 250 | ||

| 500x250x428 | 982 | 878 | 732 | 515 | 125 | 366 | 257.5 | 216 | 194 | 250 | ||

| 500x400x428 | 982 | 878 | 882 | 665 | 200 | 441 | 332.5 | 216 | 194 | 250 | ||

| 500x250x525A | 1,078 | 976 | 828 | 551 | 125 | 414 | 275.5 | 264 | 240 | 320 | ||

| 500x400x525A | 1,078 | 978 | 978 | 701 | 200 | 489 | 350.6 | 264 | 240 | 320 | ||

| 500x250x525B | 1,078 | 976 | 828 | 554 | 125 | 414 | 277 | 264 | 238 | 320 | ||

| 500x400x525B | 1,078 | 978 | 978 | 704 | 200 | 489 | 352 | 264 | 238 | 320 | ||

| Nominal size | R6 | d1 | d2 | T | θ | Welding leg length | SWL | Wire rope diameter (Recommend) | Nominal Weight | |||

| L x H x D | z1 | z2 | (kN) | (mm) | (kg) | |||||||

| 250x200x214 | 138 | 108 | 80 | 12 | 44° | 6 | 5 | 226 | 18 | 49 | ||

| 300x250x286 | 164 | 144 | 100 | 16 | 44° | 8 | 6.5 | 422 | 24 | 100 | ||

| 350x250x333 | 182 | 168 | 120 | 18 | 55° | 9 | 7 | 549 | 28 | 141 | ||

| 400x250x381 | 230 | 192 | 120 | 20 | 47° | 10 | 8 | 687 | 32 | 184 | ||

| 450x250x381 | 230 | 192 | 120 | 20 | 47° | 10 | 8 | 706 | 32 | 194 | ||

| 500x250x381 | 230 | 192 | 120 | 20 | 47° | 10 | 8 | 765 | 32 | 202 | ||

| 400x250x428 | 228 | 216 | 120 | 22 | 56° | 10 | 9 | 883 | 36 | 264 | ||

| 450x250x428 | 228 | 216 | 120 | 22 | 56° | 10 | 9 | 912 | 36 | 276 | ||

| 500x250x428 | 228 | 216 | 120 | 22 | 56° | 10 | 9 | 932 | 36 | 288 | ||

| 500x400x428 | 228 | 216 | 120 | 22 | 56° | 10 | 9 | 893 | 36 | 311 | ||

| 500x250x525A | 296 | 264 | 120 | 24 | 53° | 10 | 9.5 | 1148 | 44 | 379 | ||

| 500x400x525A | 296 | 264 | 120 | 24 | 53° | 10 | 9.5 | 1158 | 44 | 408 | ||

| 500x250x525B | 294 | 264 | 120 | 26 | 53° | 10 | 10.5 | 1413 | 44 | 405 | ||

| 500x400x525B | 294 | 264 | 120 | 26 | 53° | 10 | 10.5 | 1383 | 44 | 442 | ||

| – A Welding method may be changed based on the same welding volume / strength. | ||||||||||||

| – B SWLs shown in the Table are for reference only. These are based on the loadings as mentioned in Annex A. | ||||||||||||

| “SWL” may be adjusted depending on the actual loading conditions, and the actual marking is to be as per the agreement between the user and the manufacturer. | ||||||||||||

| – C Wire rope diameter (Recommend) is only for reference based on bending ratio of rope through the chock is 12 times. | ||||||||||||

| – D Calculated weight is for reference only. | ||||||||||||

- DOWNLOAD PDF

- Contact Us for Details !