Project Description

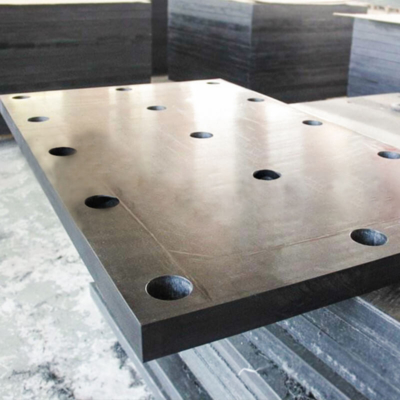

UHMWPE Fender Facing Pad

Impact resistant UHMWPE sliding panel , UHMWPE plastic marine fender front pad , UHMWPE marine dock bumper

What is the UHMWPE material:

UHMW is an Ultra High Molecular Weight Polyethylene with a molecular weight between 5 and 9 million, which is also commonly referred as UHMW, or UHMWPE.

UHMWPE Advantages:

- Self-lubricating and very low coefficient of friction;

- Excellent chemical & corrosion resistant;

- Stable chemical property and can endure the corrosion of all kind of corrosive medium and organic solvent in a certain range of temperature and humidity;

- Superior impact resistant, noise-absorption and vibration-absorption;

- Low water absorption <0.01% water absorption and not affected by temperature.

- Temperature range: -269℃~+85℃;

- Light, anti-impact, corrosion resistance, anti-ultraviolet ray, aging resistance, low friction, non-pollution, which is a good material for rubber fender face pad.

Where is the UHMWPE Fender Facing Pad applicable for:

- Marine & Jetty fenders front panel

- Quay wall protection

- Belting for barges, tugboats & supply vessels

- High-speed conveyors

- Bumpers

- Pile guards

- Wear Strips

- Guide rails

Technical Properties of UHMWPE Sheet

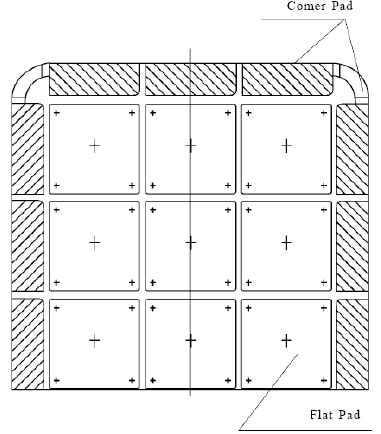

UHMWPE Sliding Sheet Installation

| Physical Properties | Test Method | Unit | Value |

|---|---|---|---|

| Density | ASTM D792 | g/cm3 | 0.93-0.97 |

| Water Absorption | ASTM D570 | ℃ | <0.01 |

| Mechanical Properties | Test Method | Unit | Value |

| Tensile Strength | ASTM D638 | MPa | 40 |

| Elongation, at break | ASTM D638 | % | 300 |

| Flexural Strength | ASTM D790 | MPa | 24 |

| Compression Strength, 10% Deformation | ASTM D695 | MPa | 21 |

| Hardness, Shore D | ASTM D2240 | – | D66 |

| Coefficient of Friction | – | – | 0.12 |

| Thermal Properties | Test Method | Unit | Value |

| Heat Deflection Temperature | ASTM D648 | ℃ | 47 |

| Melting Point | ASTM D3412 | ℃ | 135 |

| Continuous Service Temperature | – | ℃ | 82 |

| Electrical Properties | Test Method | Unit | Value |

| Surface Resistivity | ASTM D257 | Ω-M | >10 15 |

| Dielectric Constant 106Hz | ASTM D150 | 2.3 | |

| Volume resistively | ASTM D257 | Ω*cm | >10 15 |

| Dielectric strength | ASTM D604 | kV/mm | 45 |